Accelerate AR/VR/XR Eye Tracking Dev with Our Advanced Optical Metrology

We offer a comprehensive range of in-line test equipment for various applications such as camera, LED, VCSEL, display, lidar, and laser projection devices in AR/VR, smartphone, and automotive industries. Our equipment includes active-aligned optical assembly, final test, and product level OQC test stations.

Inline Production

Deploy fully inline test stations to take production to anywhere in the world

Proven Solutions

Our test station designs draw from manufacturing test solutions developed from 2005

Fairbuild can help roll out production test faster

With fairbuild, you can leverage proven test station designs and production quality software solutions from our catalog in order to accelerate concept to production cycle.

Innovative designs

At Fairbuild, we prioritize the development of R&D and manufacturing systems with clean and functional designs. Our focus is on creating intuitive interfaces that cater to the needs of test engineers, factory operators, and test station calibration sessions. We believe that multiple GUI interfaces are essential for achieving this goal.

Reduced operational cost

Collaborate with our team of seasoned professionals who possess a wealth of knowledge regarding the latest developments in optical metrology and cutting-edge solutions that are ideal for testing AR/VR components.

Medical instrument

scanning technology

for everyday use

Developed to scan micro-scratches in medical instruments this scanbed can be used in multiple research areas including electronic, textile, and optical analysis

Wide-Field Digital Microscopy Scanner

We built a Wide-Field Digital Microscopy Scanner with 360-mm x 240-mm area for Semiconductor, PCB, Materials Inspection and Medical/Biological Imaging. The specialized optics for illumination beneath the scanbed along with custom imaging optics with 1-µm pixel footprint, customizable down to 0.25-µm. The digital microscopy scanner integrates a high resolution 30-MP main camera and a secondary wide-field camera for automatic region-of-interest (ROI) identification.

Licensing production

software to reduce

operational overhead

Our production binaries have been optimized through numerous mass production cycles

License fairbuild in-house manufacturing test suite for camera, eye-tracking DOE VCSEL array, Indirect ToF, Multi-camera array, RGBD cal, DNN-ISP cal, and more.

Fairbuild has developed a range of manufacturing test suite specifically targeting AR/VR/XR core components such as cameras, lasers, ToF sensors, and DNN-ISPs. We also have a highly sophisticated indirect 3D ToF sensor calibration which can be used to independently validate ToF sensor vendor's calibration binaries.

Our binaries have been validated against production runs, allowing our customer to keep pushing the boundaries of technology to create great AR/VR/XR technologies. Our team works in close concert with the customer R&D engineers to ensure that the production tests developed are aligned with production goals and its implementation meets criteria defined to safeguard a robust manufacturing process.

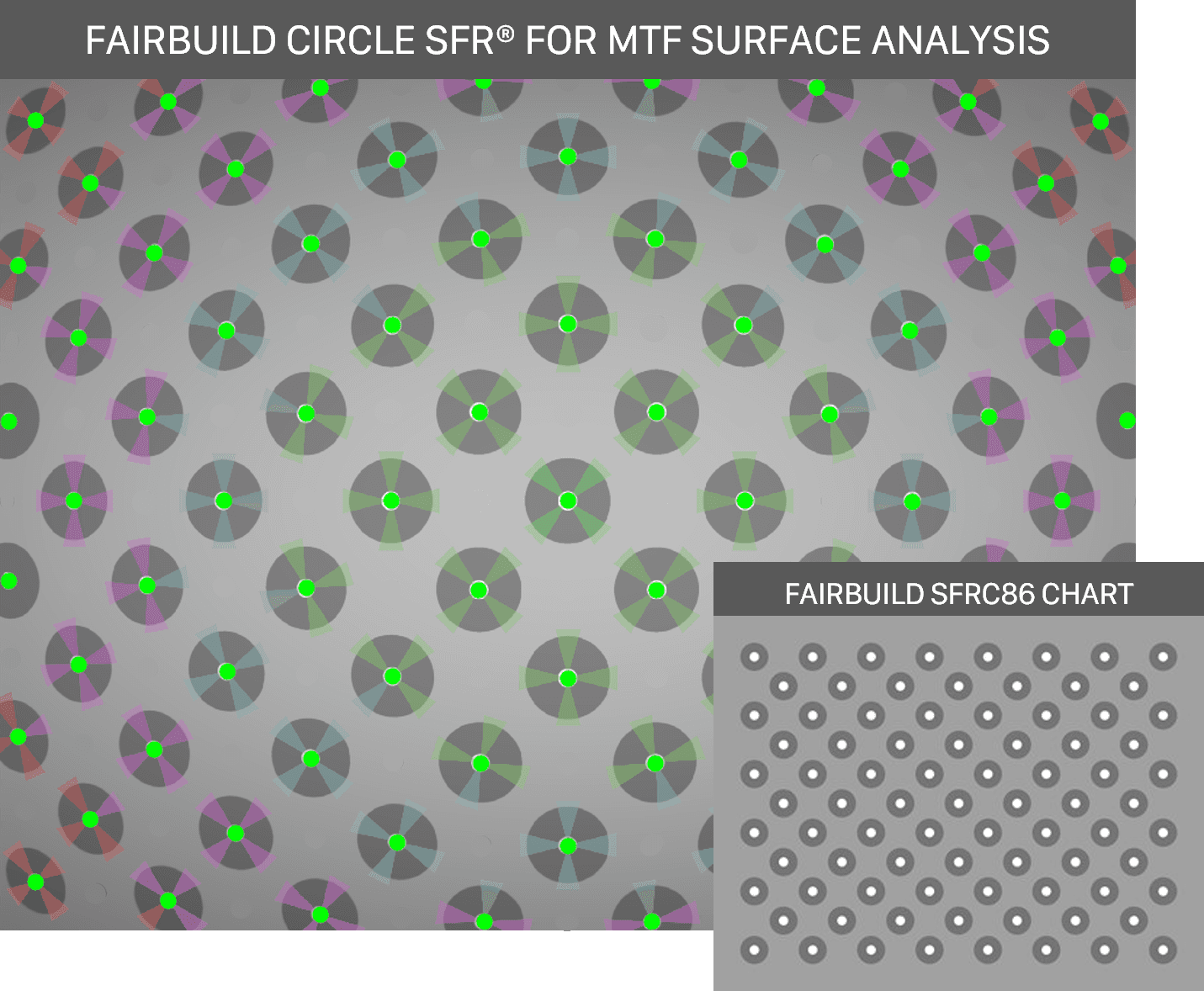

Fairbuild optical solutions can significantly reduce test station size and complexity

Fairbuild offers a variety of optical solutions, such as SFR target projectors and collimators, which can effectively reduce the size and complexity of test stations when a large virtual distance is needed. Additionally, we provide manufacturing systems for autonomous driving assistance cameras, which include active-align, intrinsic parameter calibration, and final test stations.

Have a project? let’s connect

Send us a note to reach out to our experienced staff.